Energy-efficient Insulated Siding: A Comprehensive Guide

Energy-efficient insulated siding represents a significant advancement in home exterior design, offering substantial benefits beyond mere aesthetics. This innovative siding not only enhances a home’s curb appeal but also provides superior insulation, leading to significant energy savings and reduced environmental impact. We will explore the various types, installation methods, cost-effectiveness, and long-term advantages of choosing this eco-conscious and financially savvy option for your home improvement project.

This guide delves into the specifics of energy-efficient insulated siding, covering everything from the fundamental principles of its thermal performance to detailed installation instructions and long-term maintenance strategies. We will compare different materials, analyze cost-benefit ratios, and discuss the environmental sustainability aspects of this increasingly popular choice for homeowners seeking both energy efficiency and enhanced curb appeal.

Definition and Types of Energy-Efficient Insulated Siding

Energy-efficient insulated siding represents a significant advancement in home exterior construction, offering superior thermal performance compared to traditional siding options. It combines an outer layer of aesthetically pleasing material with an inner layer of insulation, creating a more energy-efficient building envelope. This effectively reduces heat transfer, leading to lower energy bills and improved indoor comfort year-round. The fundamental principle lies in increasing the R-value of the wall system, thereby minimizing heat loss in winter and heat gain in summer.

Insulated Siding Materials

Several materials are used in the construction of energy-efficient insulated siding, each with its own set of advantages and disadvantages. The choice often depends on factors like budget, aesthetic preferences, and regional climate conditions.

Vinyl Insulated Siding

Vinyl insulated siding is a popular choice due to its affordability and low maintenance. It typically consists of a vinyl outer shell bonded to a foam insulation core, often polyisocyanurate (polyiso) or expanded polystyrene (EPS). The vinyl provides a durable, weather-resistant exterior, while the foam core offers excellent thermal insulation. However, vinyl siding’s R-value is generally lower than some other options. It’s also susceptible to damage from extreme impacts and can fade over time with prolonged sun exposure.

Fiber Cement Insulated Siding

Fiber cement insulated siding offers a more robust and durable alternative to vinyl. It combines the strength and fire resistance of fiber cement with an integrated foam insulation layer. Fiber cement is less prone to damage than vinyl and boasts a longer lifespan, often resisting fading and weathering better. However, it is generally more expensive than vinyl and requires more specialized installation techniques. The higher density and thicker nature of fiber cement often leads to a higher R-value compared to vinyl insulated siding.

Foam-Core Insulated Siding

Foam-core insulated siding uses a rigid foam insulation board as its primary component, with a thin outer layer of a facing material such as vinyl, aluminum, or fiber cement. This design allows for very high R-values, making it exceptionally energy-efficient. The choice of facing material impacts the aesthetic appeal, durability, and maintenance requirements. For example, an aluminum-faced foam-core siding might be chosen for its superior weather resistance in coastal areas. However, foam-core siding is generally more expensive than other types and can be more susceptible to damage during installation if not handled carefully.

Comparison of Thermal Performance and Other Factors

The following table summarizes the key characteristics of different insulated siding materials:

| Siding Material | R-Value (Approximate) | Cost (Relative) | Maintenance Requirements |

|---|---|---|---|

| Vinyl Insulated Siding | R-4 to R-8 | Low | Low; occasional cleaning |

| Fiber Cement Insulated Siding | R-6 to R-10 | Medium to High | Medium; periodic painting or sealing may be needed |

| Foam-Core Insulated Siding | R-10 to R-20+ | High | Low to Medium; depending on facing material |

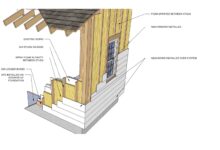

Installation Methods and Best Practices

Proper installation of energy-efficient insulated siding is crucial for maximizing its energy-saving benefits and ensuring its longevity. A poorly installed system can lead to air leaks, moisture intrusion, and reduced thermal performance, negating the advantages of the insulated siding itself. This section details installation methods for two common types and outlines best practices to ensure a successful and efficient installation.

Installation of Insulated Vinyl Siding

Insulated vinyl siding typically consists of a vinyl outer layer bonded to a foam insulation core. Installation generally follows these steps:

- Preparation: Begin by preparing the existing wall surface. This includes removing old siding, repairing any damaged sheathing, and ensuring the surface is clean and dry. Proper preparation is key to a successful installation.

- Measuring and Cutting: Accurately measure and cut the siding panels to fit the wall sections. Use sharp tools to avoid damaging the vinyl.

- J-Channel Installation: Install J-channels around windows, doors, and corners to provide a finished edge and allow for expansion and contraction of the siding.

- Siding Panel Installation: Starting at a corner, install the siding panels, overlapping them slightly and securing them with nails or screws into the sheathing, avoiding over-driving fasteners.

- Finishing: Install trim pieces, such as corner trim and window/door trim, to complete the installation and provide a neat, finished appearance.

Installation of Insulated Fiber Cement Siding

Insulated fiber cement siding offers superior durability and fire resistance compared to vinyl. Installation involves similar steps, but with some key differences:

- Preparation: Similar to vinyl siding, prepare the wall surface by removing old siding, repairing any damage, and ensuring a clean, dry surface. Pay particular attention to ensuring a level and plumb surface for fiber cement, as it is less flexible than vinyl.

- Furring Strips (Optional): For added insulation and improved air sealing, consider installing furring strips to create an air gap between the wall and the siding. This is particularly beneficial in climates with significant temperature fluctuations.

- Measuring and Cutting: Measure and cut the fiber cement panels precisely, using a wet saw to avoid dust and ensure clean cuts. Fiber cement is harder to cut than vinyl, requiring specialized tools.

- Panel Installation: Install the panels, ensuring proper overlap and alignment. Use corrosion-resistant fasteners appropriate for fiber cement.

- Caulking and Sealing: Carefully caulk all seams and joints to prevent moisture penetration and air leaks. This is especially critical with fiber cement due to its susceptibility to moisture damage.

Best Practices for Energy-Efficient Siding Installation

To maximize energy efficiency, several best practices should be followed:

- Air Sealing: Pay close attention to air sealing around windows, doors, and other penetrations. Use appropriate sealant and backer rod to ensure a complete seal.

- Proper Fastening: Use the correct fasteners and avoid over-driving them, which can damage the siding and compromise its structural integrity.

- Moisture Management: Ensure proper ventilation behind the siding to prevent moisture buildup. Consider using a moisture barrier if necessary.

- Continuous Insulation: For optimal thermal performance, aim for continuous insulation throughout the wall system, minimizing thermal bridging.

Potential Installation Challenges and Solutions

Several challenges may arise during installation:

- Uneven Wall Surfaces: Uneven surfaces can make it difficult to install siding evenly. Solutions include shimming or using furring strips to create a level surface.

- Difficult-to-Reach Areas: Reaching high or narrow areas can be challenging. Solutions include using scaffolding or extending tools.

- Damage to Siding: Careless handling can damage the siding. Solutions include careful handling and use of appropriate tools.

- Incorrect Fastener Placement: Improper fastener placement can lead to leaks or damage. Solutions include using a level and measuring carefully.

Installation Checklist

A comprehensive checklist can help ensure a successful installation:

| Step | Completed |

|---|---|

| Wall Surface Preparation | ☐ |

| J-Channel/Flashing Installation | ☐ |

| Siding Panel Installation | ☐ |

| Caulking and Sealing | ☐ |

| Trim Installation | ☐ |

| Final Inspection | ☐ |

Energy Savings and Cost-Effectiveness

Investing in energy-efficient insulated siding offers significant long-term benefits, extending beyond the initial purchase price. The enhanced insulation properties directly translate into reduced energy consumption, leading to lower utility bills and a positive return on investment. This section details the potential energy savings and the overall cost-effectiveness of this upgrade compared to traditional siding options.

The primary advantage of insulated siding lies in its ability to significantly reduce heat transfer through the exterior walls of a home. In colder climates, this means less heat escapes during winter, minimizing the demand on your heating system. Conversely, in warmer climates, the siding helps keep the interior cool, reducing reliance on air conditioning. This reduced energy consumption directly translates into lower monthly energy bills, a benefit that accumulates over the lifetime of the siding.

Financial Benefits of Energy Savings

Energy savings from insulated siding manifest in tangible financial benefits for homeowners. For example, a homeowner in a region with harsh winters might see a reduction of 15-25% in their annual heating costs. This translates to hundreds, or even thousands, of dollars saved each year, depending on the size of the home and the climate. These savings can be used to offset other household expenses, contribute to home improvements, or simply increase disposable income. Furthermore, the improved energy efficiency can increase the home’s resale value, making it a worthwhile investment even if the homeowner plans to move in the future.

Comparative Cost Analysis

The following table compares the initial cost, estimated annual energy savings, and return on investment (ROI) for different siding types. These figures are estimates and will vary based on factors such as climate, home size, energy prices, and the specific products used. It’s crucial to obtain accurate quotes from local contractors for your specific situation.

| Siding Type | Initial Cost (Estimate) | Estimated Energy Savings per Year (Estimate) | Return on Investment (Estimate, Years) |

|---|---|---|---|

| Traditional Vinyl Siding | $10,000 – $15,000 | $100 – $300 | 33 – 150+ |

| Insulated Vinyl Siding | $15,000 – $25,000 | $500 – $1000 | 15 – 25 |

| Fiber Cement Siding with Foam Insulation | $20,000 – $35,000 | $700 – $1500 | 14 – 25 |

Note: These figures are illustrative examples and may not reflect actual costs in all regions. Consult with local contractors for accurate pricing and energy savings projections. ROI calculations assume a constant annual energy savings over the lifespan of the siding.

Environmental Impact and Sustainability

Energy-efficient insulated siding offers significant environmental advantages compared to traditional siding materials. Its inherent ability to reduce energy consumption translates directly into a smaller carbon footprint for buildings and a lessened strain on natural resources. This section explores the environmental benefits, material comparisons, sustainable manufacturing practices, and the overall contribution to carbon reduction.

The environmental benefits of energy-efficient insulated siding stem primarily from its impact on building energy efficiency. By reducing the amount of energy needed to heat and cool a home, these materials lessen the demand on power plants, which often rely on fossil fuels. This reduction in energy consumption directly translates to a lower emission of greenhouse gases, mitigating climate change. Furthermore, the inherent insulation properties contribute to a reduction in thermal bridging, further minimizing energy loss and maximizing energy savings.

Environmental Impact of Different Insulated Siding Materials

Different insulated siding materials possess varying environmental impacts throughout their lifecycle, from raw material extraction and manufacturing to disposal. For instance, fiber cement siding, while durable and long-lasting, often requires significant energy during manufacturing. On the other hand, vinyl siding, while readily available and relatively inexpensive, is derived from petroleum and contributes to plastic waste at the end of its life. Engineered wood siding, while utilizing a renewable resource, may still require significant processing and potentially contain added chemicals. A comprehensive life-cycle assessment (LCA) is crucial for comparing the overall environmental impact of each material. Such an assessment would consider factors such as embodied carbon (the carbon emissions associated with the production and transportation of the material), energy consumption during manufacturing, and the material’s end-of-life management options. A thorough LCA allows for a more informed decision regarding the most environmentally responsible choice.

Sustainable Manufacturing Practices

Sustainable manufacturing practices are crucial in minimizing the environmental impact of energy-efficient insulated siding. These practices include utilizing recycled materials in the production process, reducing energy consumption through process optimization, and implementing waste reduction strategies. For example, manufacturers may incorporate recycled plastic or wood fibers into their siding formulations, diverting waste from landfills and reducing reliance on virgin materials. Furthermore, employing renewable energy sources, such as solar or wind power, in the manufacturing facilities can significantly lower the carbon footprint associated with production. Implementing rigorous quality control measures can extend the lifespan of the siding, further reducing the need for frequent replacements and minimizing waste generation over time. Finally, responsible sourcing of raw materials, ensuring sustainable forestry practices and minimizing environmental damage, plays a vital role in creating a truly sustainable product.

Contribution to Reducing Carbon Footprint

The use of energy-efficient insulated siding directly contributes to reducing a building’s carbon footprint. The reduced energy consumption for heating and cooling translates to lower greenhouse gas emissions, a key factor in mitigating climate change. For example, a home retrofitted with energy-efficient insulated siding might experience a 20-30% reduction in heating and cooling costs, leading to a corresponding decrease in energy-related CO2 emissions. This reduction can be significant, particularly when considering the cumulative effect of widespread adoption of such materials across a community or region. Furthermore, the longer lifespan of high-quality insulated siding, compared to some traditional options, reduces the need for frequent replacements, further minimizing material waste and associated emissions. This longevity aspect contributes significantly to the overall environmental sustainability of the product over its entire lifecycle.

Maintenance and Lifespan

Proper maintenance significantly impacts the longevity and energy efficiency of your insulated siding. Regular care prevents costly repairs and ensures your siding continues to provide optimal thermal performance and aesthetic appeal for years to come. Neglecting maintenance can lead to premature deterioration, compromising both the energy efficiency and the visual appeal of your home.

Regular inspection and prompt attention to minor issues can prevent them from escalating into major, expensive problems. Different siding materials require slightly different maintenance routines, but the core principles of cleanliness and prompt repair remain consistent.

Routine Maintenance Procedures for Different Siding Types

Different types of energy-efficient insulated siding, such as vinyl, fiber cement, and engineered wood, each have unique maintenance requirements. Vinyl siding generally requires only occasional cleaning, while fiber cement may need periodic painting or sealing. Engineered wood siding often necessitates more frequent inspections for signs of moisture damage.

- Vinyl Siding: Regularly wash with a mild detergent and water solution using a soft brush or sponge. Avoid abrasive cleaners or high-pressure washers, which can damage the surface. Inspect for cracks or loose seams and address any issues promptly.

- Fiber Cement Siding: Clean with a mild detergent and water solution, paying attention to removing any dirt or mildew buildup. Inspect for cracks or damage. Repainting or resealing may be necessary every 5-10 years depending on climate and exposure to the elements.

- Engineered Wood Siding: This type of siding requires more frequent inspection for signs of moisture damage, such as swelling or discoloration. Regularly clean with a soft brush and mild detergent. Apply a water-repellent sealant every few years to protect against moisture.

How Proper Maintenance Extends Lifespan

Consistent maintenance significantly extends the lifespan of your energy-efficient insulated siding. Addressing minor issues promptly prevents them from escalating into larger, more costly problems. For example, a small crack in vinyl siding, if left unaddressed, can allow water penetration, leading to rot and potential structural damage. Regular cleaning prevents the buildup of dirt and mildew, which can degrade the siding material over time. Protective sealants help maintain the integrity of the siding and its insulation properties, preventing premature wear and tear. A well-maintained siding system can easily last for 20-30 years or even longer, depending on the material and the level of care provided.

Common Problems and Their Solutions

Several common issues can affect energy-efficient insulated siding. These include:

- Cracks and Gaps: These can allow water penetration, leading to rot and damage. Repair with appropriate caulking or patching materials specific to the siding type.

- Mildew and Mold: Clean with a solution of bleach and water (follow manufacturer’s instructions). Prevent future growth by ensuring proper ventilation and drainage.

- Loose or Damaged Panels: Replace damaged panels as needed. Ensure proper fastening to prevent further issues.

- Insect Infestation: Address infestations promptly using appropriate insecticides and sealing any entry points.

Maintenance Schedule

A regular maintenance schedule helps prevent problems and extends the lifespan of your siding. Here’s a recommended plan:

- Annual Inspection: Visually inspect all siding for damage, cracks, loose panels, or signs of insect infestation. Clean gutters and downspouts to ensure proper water drainage.

- Spring Cleaning: Wash siding with a mild detergent and water solution. Remove any dirt, debris, or mildew buildup.

- Every 2-3 Years: For engineered wood siding, apply a water-repellent sealant to protect against moisture damage. For fiber cement siding, consider repainting or resealing if necessary.

- As Needed: Repair any cracks, gaps, or damaged panels promptly. Address any signs of insect infestation or moisture damage immediately.

Visual Appeal and Design Considerations

Energy-efficient insulated siding offers a compelling blend of functionality and aesthetics, allowing homeowners to enhance their curb appeal while improving energy efficiency. The wide variety of colors, textures, and styles available ensures that there’s an option to complement virtually any architectural style and personal preference.

The aesthetic appeal of energy-efficient insulated siding stems from its ability to mimic the look of traditional materials like wood, brick, or stone, while offering superior durability and insulation properties. This allows homeowners to achieve a high-end, sophisticated look without the high maintenance costs associated with more traditional materials. Modern manufacturing techniques allow for incredibly realistic textures and colors, from the subtle grain of wood to the rough texture of stone, expanding the design possibilities significantly.

Color and Texture Enhancements

Different colors and textures can dramatically impact a home’s exterior. Light colors, such as creamy whites or soft grays, can create a feeling of spaciousness and reflect sunlight, reducing cooling costs. Darker colors, like deep blues or browns, can provide a more dramatic and sophisticated look, but may absorb more heat. Similarly, the texture of the siding can add depth and visual interest. A smooth surface offers a clean, modern look, while a textured surface can create a more rustic or traditional feel. For example, a home with a Craftsman style could benefit from siding with a deeply textured wood-grain finish, while a contemporary home might be better suited to smooth, flat panels in a bold color.

Integrating Insulated Siding with Architectural Elements

Careful consideration should be given to how the insulated siding interacts with other architectural elements such as windows, doors, and roofing. The siding should complement, not clash, with these features. For instance, a home with large, prominent windows might benefit from siding with a simpler, less textured finish to avoid overwhelming the architectural details. Conversely, a home with smaller windows or simpler architectural features might benefit from siding with a more prominent texture or color to add visual interest. Matching or coordinating the siding color with the roof or trim can create a cohesive and visually appealing exterior. The use of contrasting colors or textures can also be effective in creating visual interest and highlighting certain architectural details.

Siding Styles and Colors for Different Architectural Styles

Imagine a Victorian-style home adorned with deeply textured, dark brown insulated siding that mimics the look of aged wood clapboard. The intricate detailing of the home is accentuated by the siding’s rich color and texture. Contrast this with a sleek, modern home clad in smooth, light gray insulated panels, creating a clean, minimalist aesthetic. The straight lines and uncluttered design of the house are complemented by the siding’s simple elegance. A farmhouse-style home might be beautifully complemented by light beige or creamy white insulated siding with a subtle wood-grain texture, evoking a sense of warmth and rustic charm. Finally, a traditional colonial home might be beautifully accented by crisp white or off-white insulated siding with dark green or black shutters, creating a classic and timeless look. The variety of colors and textures allows for a high degree of customization to suit individual preferences and architectural styles.

Closing Notes

Ultimately, the decision to invest in energy-efficient insulated siding is a multifaceted one, balancing initial costs with long-term savings, aesthetic preferences with environmental responsibility. By carefully considering the various factors discussed—from material selection and installation techniques to ongoing maintenance and potential energy savings—homeowners can make an informed choice that best suits their individual needs and contributes to a more sustainable and comfortable living environment. The improved insulation, reduced energy bills, and enhanced visual appeal make energy-efficient insulated siding a worthwhile investment for many homeowners seeking a blend of practicality and aesthetic enhancement.